About us

About us

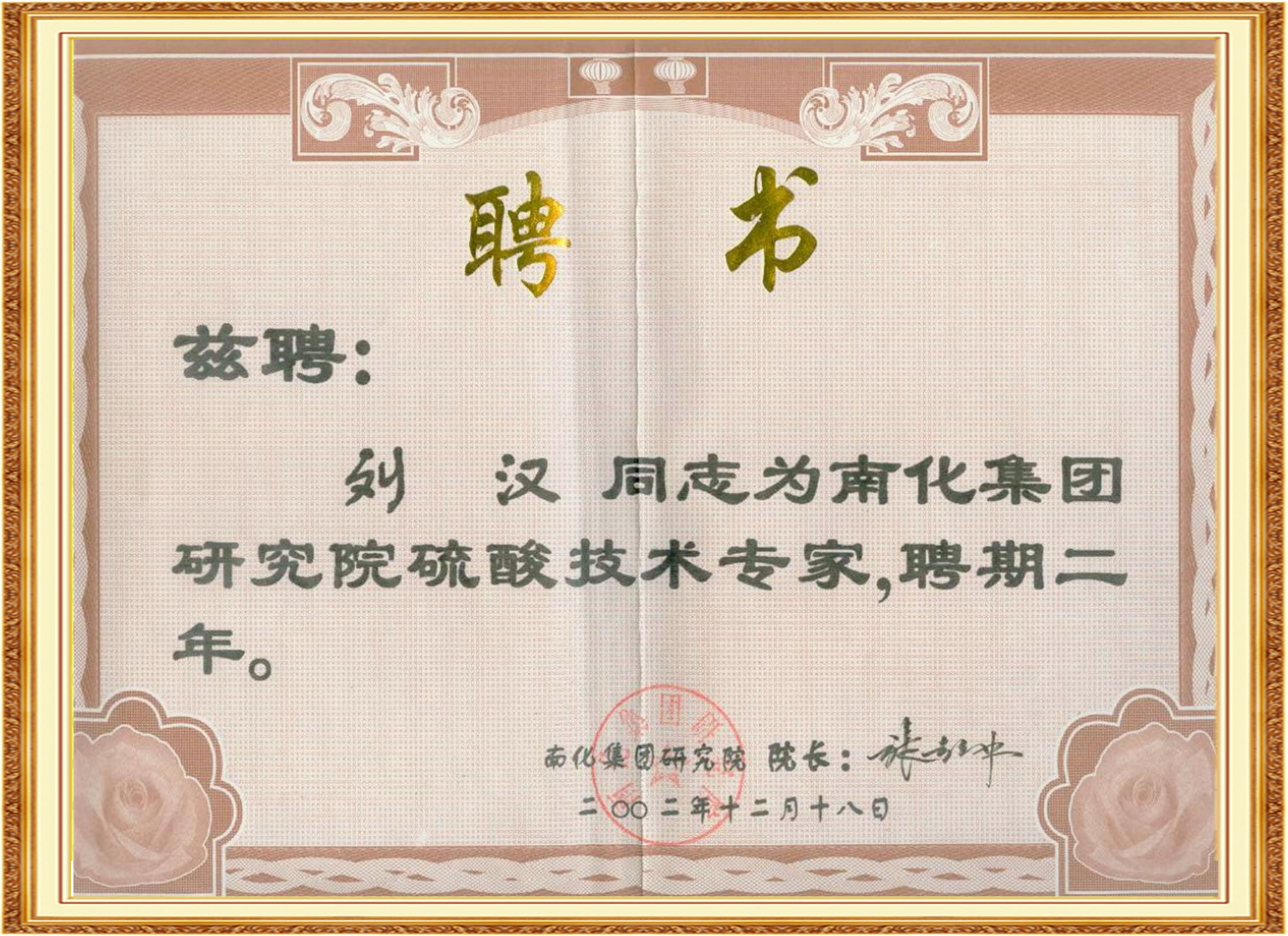

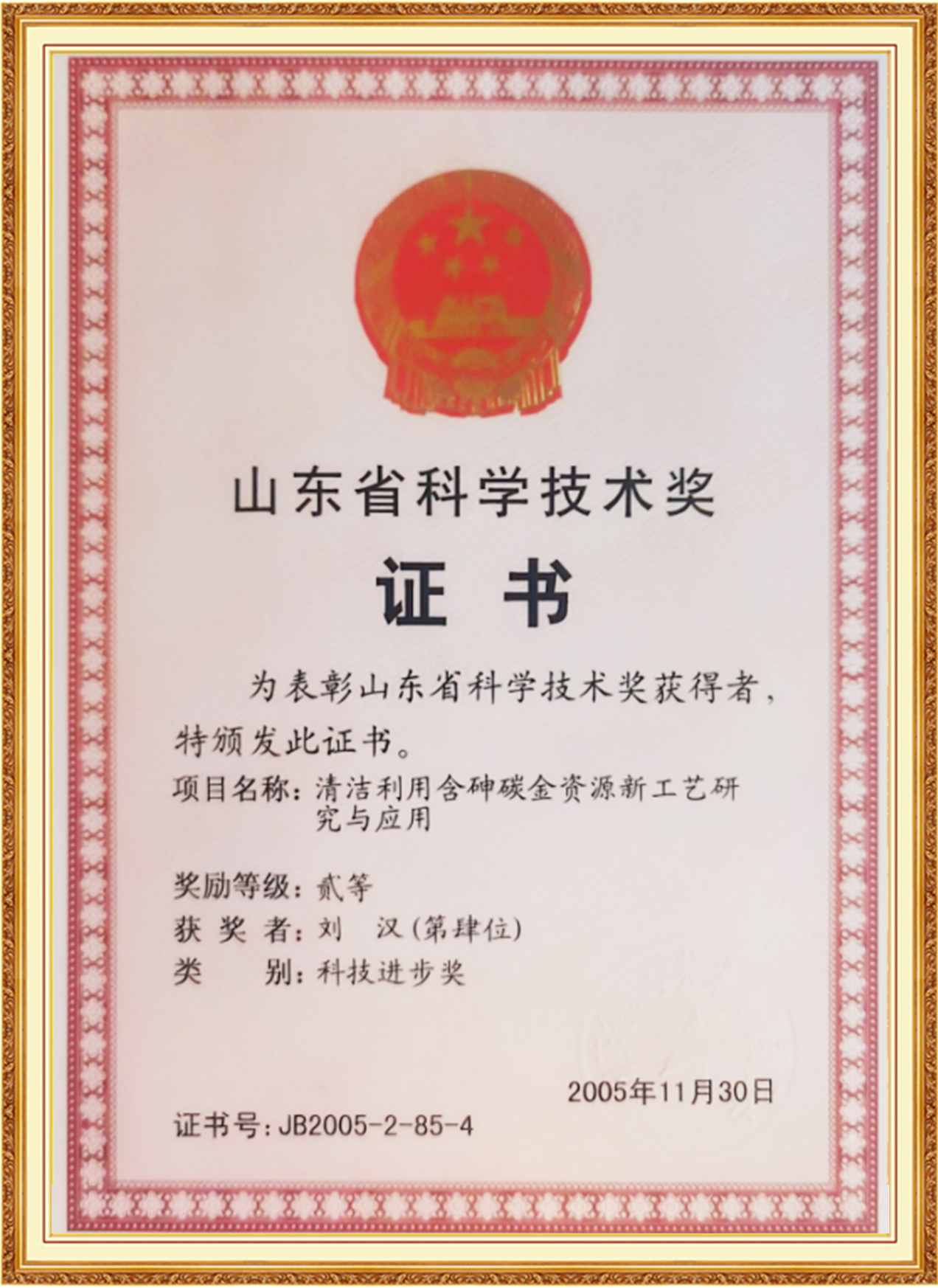

Anhui Yiliu Environmental Technology Co., Ltd. is a professional manufacturer of sulfuric acid complete equipment, desulfurization complete equipment, and garbage treatment complete equipment. The company is located between Jingqi Road and Jingba Road in the High tech Development Zone of Tianchang City, Anhui Province, 50km away from Nanjing and 40km away from Yangzhou. The company covers an area of 50 acres, with a factory building of 15000m2 and advanced and complete processing equipment. The company has a total of 122 employees, including 35 engineering and technical personnel with college degrees or above, and 15 senior engineers and sulfuric acid experts. The company is located adjacent to the China Sulfuric Acid Research and Design Center, Nanhua Group Research Institute, and Nanhua Design Institute, and has abundant sulfuric acid technology resources and design personnel resources. The company has rich experience in chemical equipment manufacturing and strong technical strength, with professional and complete technical personnel and complete design facilities. The production equipment is advanced, the variety and specifications are complete, the quality is stable and reliable, and the products are sold throughout the country. |

The company strictly manages in accordance with the ISO9001-2015 international quality system and has strong technical strength and development team. To meet the special requirements of customers for products, we can customize personalized products for you. The company enjoys a high reputation among peers nationwide in terms of product quality, sales, and after-sales service. The company has hired experts in acid production and desulfurization, who provide technical support year-round and offer suggestions and continuous innovation for our company. Our company relies on the design institute of Nanhua Group, the research institute of Nanhua Group, Beijing Nonferrous Metallurgy Design Institute, Changsha Nonferrous Institute, Yunnan Chemical Industry Design Institute and other technical support throughout the year. With the most advanced technology and standardized management, we conduct technical checks on our company's projects.

Main business

Main business

1. Sulfur foam, desulfurization waste liquid (wet, semi dry, dry) sulfuric acid production, salt extraction, refined sulfur EPC project. 2. The general contracting project for hydrogen sulfide wet process, dry process acid production, and Claus sulfur production. 3. The complete general contracting project for sulfuric acid production from pyrite. 4. Sulfur based sulfuric acid complete set general contracting project. 5. The general contracting project for acid production through two-stage roasting of gold concentrate and arsenic containing gold concentrate, including desulfurization, arsenic removal, and decarbonization. 6. General contracting project for acid production from smelting flue gas of non-ferrous metals such as copper, lead (including regenerated lead), zinc, molybdenum, cobalt, etc. 7. Low temperature heat recovery general contracting project for pyrite, sulfuric acid production, and acid production from smelting flue gas. 8. General contracting project for waste sulfuric acid cracking, ammonium sulfate incineration for acid production, and dilute acid concentration. 9. Contracting of low concentration SO2 activated carbon, organic amines, and ionic liquid adsorption desorption for sulfuric acid production project; 1%~4.5% low concentration SO2 one-step acid production contracting project. | 10. MVR evaporation and multi effect evaporation complete equipment general contracting project for high salt wastewater. 11. The general contracting project for complete sets of equipment for hydrogen peroxide desulfurization, limestone gypsum desulfurization, ammonia desulfurization, sodium alkali desulfurization, denitrification, whitening, and garbage incineration. 12. Mannheim process potassium sulfate, hydrochloric acid, liquid sulfur dioxide, liquid sulfur trioxide, refined sulfuric acid, chlorosulfonic acid general contracting project. 13. Manufacturing and installation of individual equipment such as boiling furnaces, incinerators, cracking furnaces, rotary kilns, electrostatic precipitators, electrostatic demisters, bag filters, high-temperature filtration dust collectors, power wave scrubbers, dilute acid filters, fiber demisters, glass tube sulfuric acid condensers, heat exchangers, converters, and dry absorption towers. 14. Manufacturing and installation of fiberglass electric defoggers, storage tanks, towers, and pipelines. 15. Supply and construction of instruments such as thermometers, pressure gauges, temperature sensors, pressure transmitters, level gauges, flow meters, analytical instruments, cable trays, and cables for sulfuric acid production. |